Revolutionary Electronic Ink Enables Shape-Shifting Electronics

Scientists have developed a groundbreaking electronic ink capable of switching between rigid and soft states when heated, opening exciting possibilities for next-generation flexible electronics and medical devices.

Shape-Shifting Technology: From Rigid to Soft on Demand

Researchers have created a novel electronic ink that combines gallium, a metal that transitions from solid to liquid near body temperature, with a polymer-based solvent. This innovative material allows printed circuits to change stiffness in response to temperature, paving the way for devices that adapt to their environment.

This technology addresses a significant challenge in electronics manufacturing: the trade-off between rigid devices (offering high performance and durability) and soft devices (prioritizing comfort and flexibility). The new electronic ink bridges this gap, enabling devices to seamlessly transition between hard and soft states as needed. This functionality has significant implications for various applications, from wearable technology to medical implants.

Overcoming the Challenges of Liquid Metal Printing

Using gallium in printed electronics has historically been difficult due to its high surface tension and tendency to oxidize. The research team overcame these challenges by developing a process for dispersing microscopic gallium particles into a polymer matrix using dimethyl sulfoxide (DMSO) as a solvent.

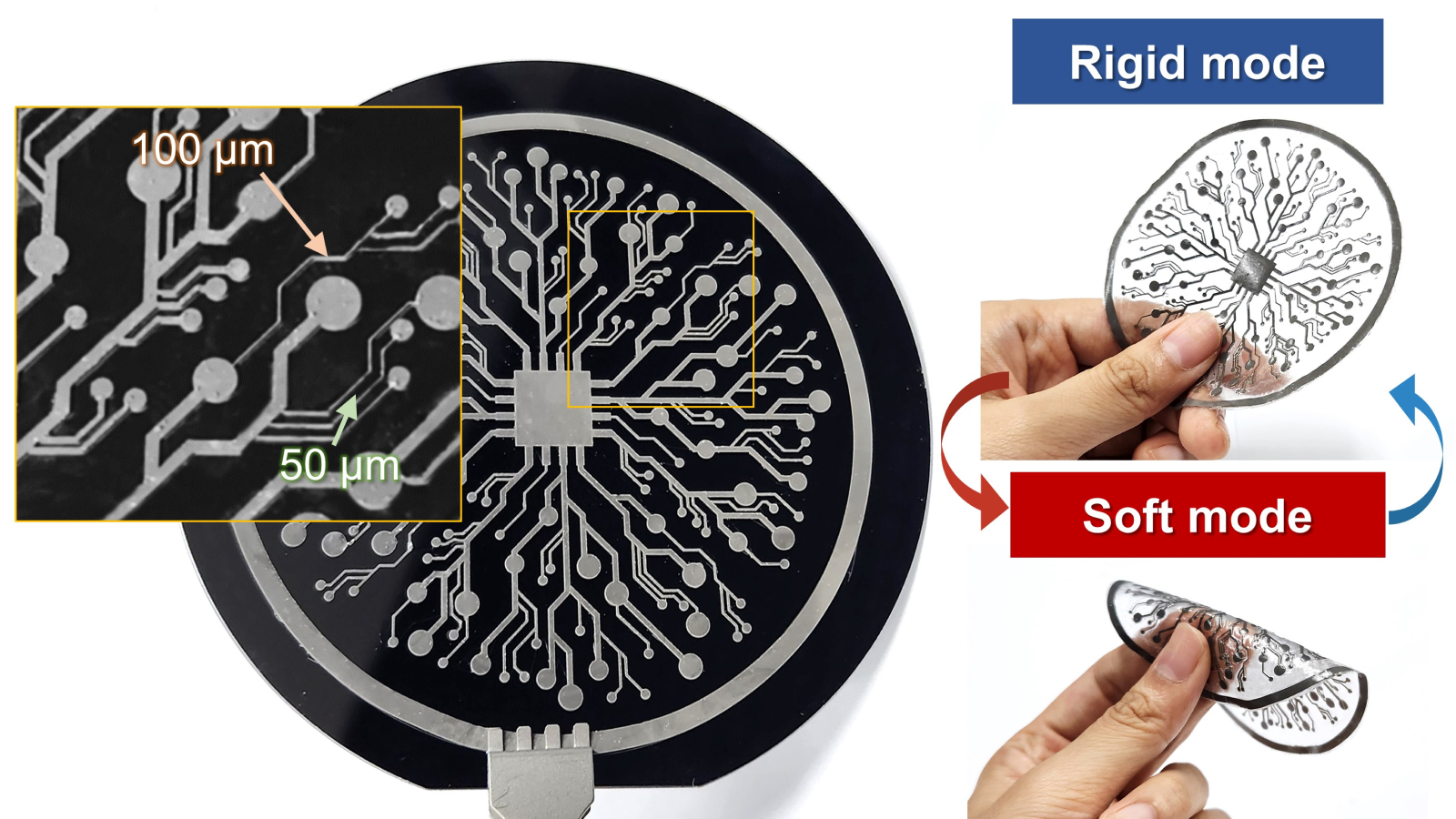

Gently heating the printed circuit breaks down the solvent, creating a slightly acidic environment that removes the oxide layer from the gallium particles. This allows the particles to melt and merge, forming conductive pathways. The result is a stable, printable substance capable of creating features as small as 50 micrometers—thinner than a human hair. This precision, combined with the material’s tunable stiffness, opens up a vast array of potential applications.

Applications and Implications: Wearables, Implants, and Beyond

The researchers demonstrated the potential of their invention by creating two functional devices. One was a wearable health device that remains rigid at room temperature for portability and then softens upon contact with skin for enhanced comfort. The other was a flexible brain implant designed to remain rigid during surgery for precise insertion and then soften inside the brain to minimize irritation and inflammation.

The versatility of this electronic ink extends beyond these examples. Its compatibility with common manufacturing techniques like screen printing and dip coating suggests potential for large-scale production and integration into 3D-printed electronics. The ability to create shape-shifting devices with tunable stiffness opens up exciting possibilities for a wide range of applications, including flexible robotics, advanced medical devices, and consumer electronics.

The Future of Flexible Electronics: A Paradigm Shift

This groundbreaking development represents a significant advancement in the field of flexible electronics. The ability to create circuits that seamlessly transition between rigid and soft states on demand has the potential to revolutionize various industries.

The technology’s compatibility with existing manufacturing techniques further enhances its potential for widespread adoption. This innovation could lead to more comfortable and adaptable wearable devices, less invasive and more effective medical implants, and more versatile and responsive robotic systems. The implications for the future of electronics are vast and transformative.

Key Takeaways

- A new electronic ink allows printed circuits to switch between rigid and soft states when heated.

- This innovation overcomes challenges associated with using liquid metals in printed electronics.

- The technology enables the creation of shape-shifting devices with tunable stiffness.

- Potential applications include wearable technology, medical implants, and flexible robotics.

- This breakthrough has the potential to revolutionize the field of flexible electronics.